Here's a U2 model next to an SD 160 model over the bays.

On the U2 model, you can see the coupler. The lower part is the mechanical coupling and the top part is electronic with its array of pins (kind of like an old printer cable for your computer). On the newest models (Series 8), there are a few more pins which are for the video camera feed and newer features like that.

A look along the bays where CT mechanics can work on the underside of the LRVs.

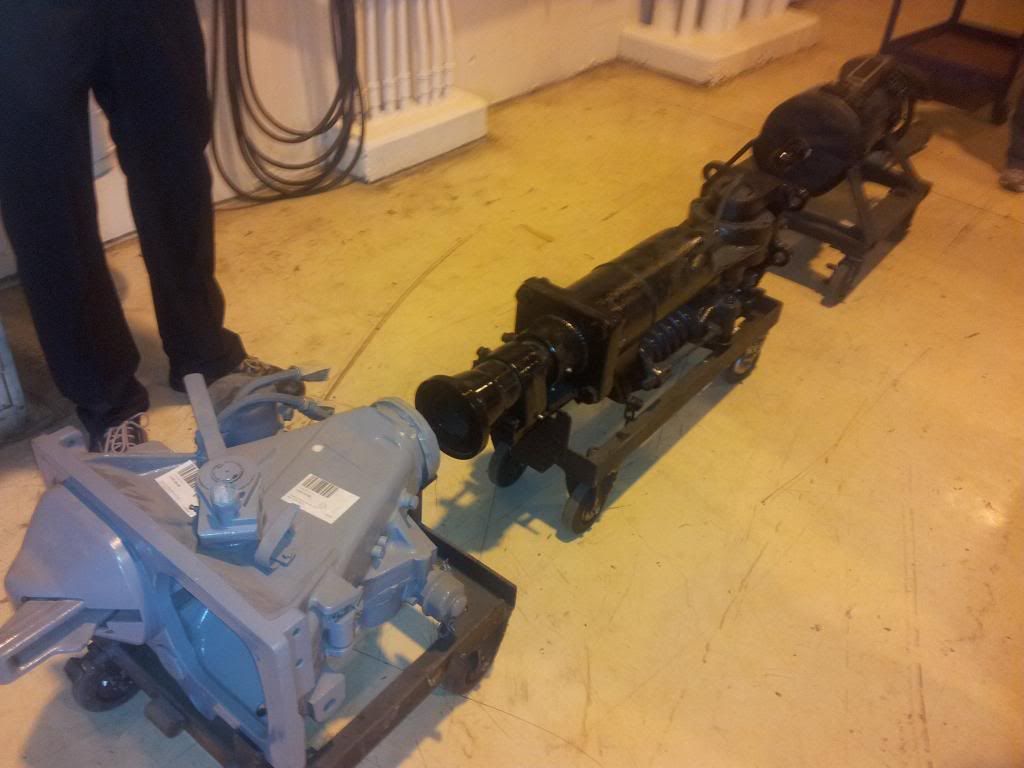

A closer look at a coupling system. The middle piece is a shock absorber. You can see the coils of the spring on the underside of it.

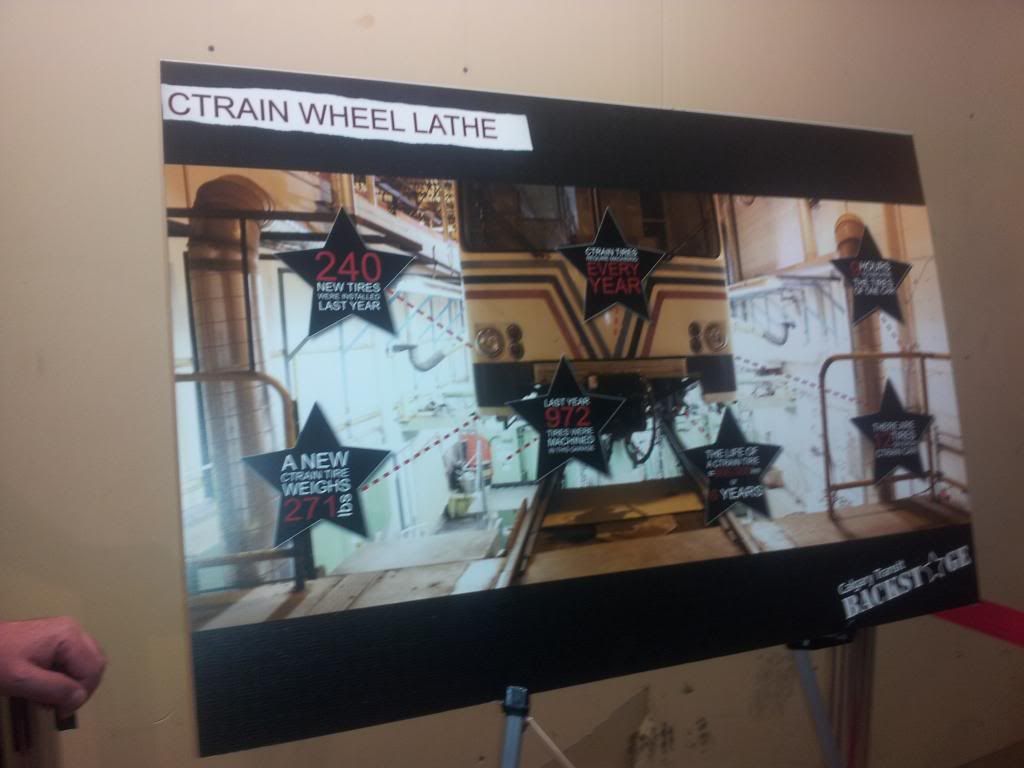

Some wheel lathe information. Sorry for the blur. I thought I had taken pictures of the actual lathe but I somehow missed that. Anyway, it's where the LRV wheels are serviced. The wheels will wear so that their profile no longer matches the track and are "flat" and make for a bumpy and eventually dangerous ride. The wheels themselves are actually two halves that are clamped together.

Storage lanes

Banged-up U2 unit 2057, or at least half of it. The other half now forms part of the "new" car 2090.

Another U2 car that is undergoing heavy work. The various components were taken out and put on display for the tour.

Pantograph (the part of the train that connects to the overhead catenary wire to draw power). Sorry for the blur.

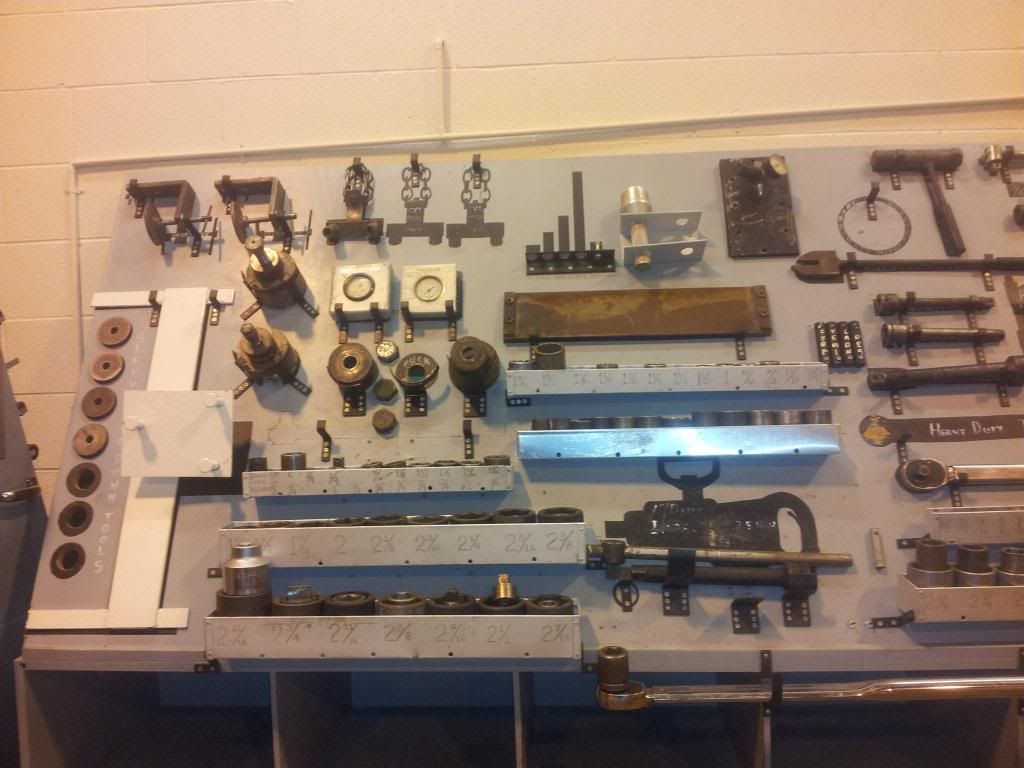

Tools used by diesel bus mechanics.

Old diesel engine.

Refurbished unit. Same as above. They are rebuilt every 300 000 km.

Old 2 stroke Detroit Diesel

Allison transmission

Various other components

Transit Teddy's golf cart "bus"

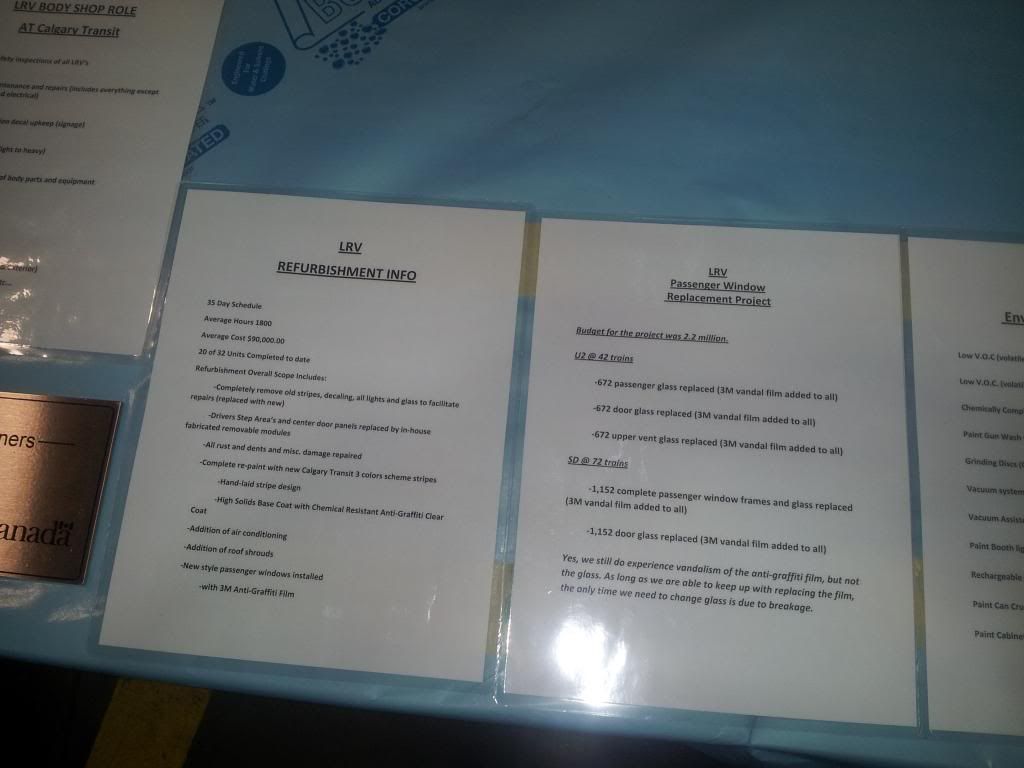

Lots of LRVs are undergoing refurbishment now. Here is some information on that.

Paint/window shop. Here is an SD160 unit having its windows replaced.

Doing some body work on the door and other areas of the train.

Steps for driver (and when passengers need to be offloaded in an emergency). This unit did not come with the train and was fabricated by Calgary Transit workers because the units that came from the manufacturer had problems. They did this with all trains and eventually the manufacturer adopted CT's design and uses it on their new trains.

Bus service lane. All buses must pass through here after going off shift to have tires checked, be refueled and have some other quick checks done.

Compressed Natural Gas bus. One of three purchased by CT as a pilot. These currently run on the 72/73 route. This allows the buses to be tested in a variety of environments, conditions, tight turns, etc. There had been some natural gas buses demonstrated a few years ago but the technology just wasn't there and they struggled in the harsh winter environment. This is no longer a problem with these newer models. Sounds like there are going to be a lot more of these ordered.

Inside the cab of an SD160 LRV. We were taken through the wash and a brief tour of the yard.

Another look at the diesel shop with some bus units undergoing mechanical work.